Relief printing, or the relief printing process, is a printing technique in which the printing elements lie on the higher level.

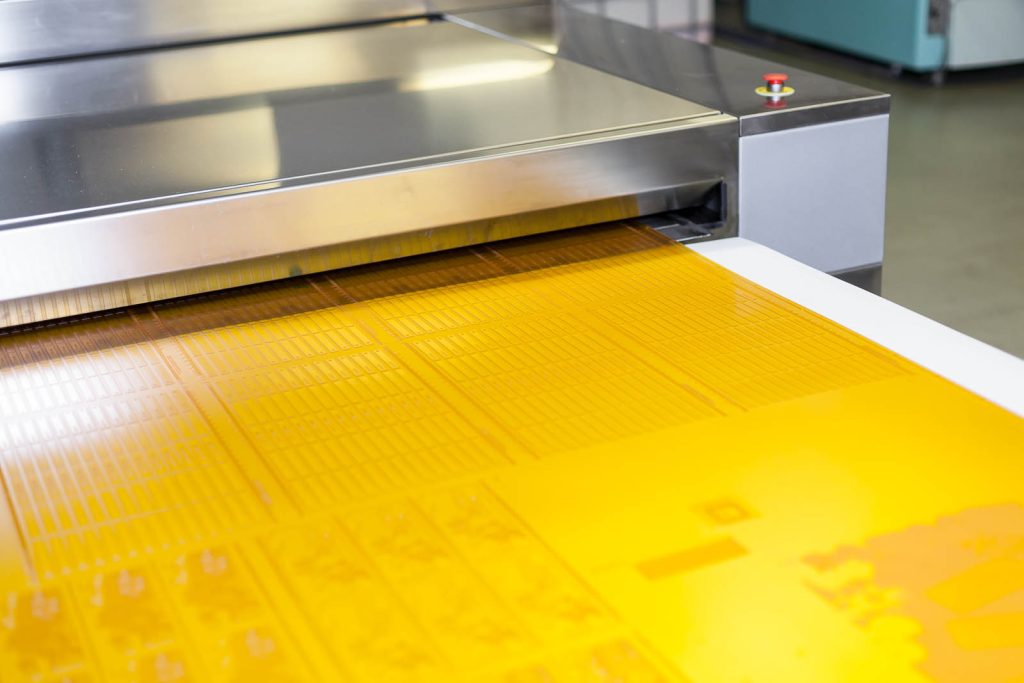

As with a rubber stamp, only the protruding parts, the image-carrying parts, of the printing plate are covered with ink and produce the print image. The lower surface is referred to as the non-printing part.

The print image is reversed on the image carrier so that it will appear the correct way round on the print substrate. Relief printing is divided into two print methods: letterpress and the more recent flexography.